How is greenhouse glass (scattering glass, anti-reflective glass, diffuse reflection glass) made?

In the current greenhouse market, the glass that can be used in glass greenhouses can be divided into two major categories, ultra-white scattering glass and ultra-white anti-reflection glass. Both types of glass are deep-processed products of ultra-white float glass.

Greenhouse glass has its own technical standards, so compared with other types of glass, it has its own characteristics.

The manufacturing of greenhouse glass is divided into three processes, raw sheet production, tempering processing, and coating processing. Today, let's learn what types of glass can be produced in these three steps.

Raw sheet production (here taking Yuhua glass as an example)

Yuhua's raw sheet production process is: mixing -> melting -> calendering printing -> air cooling molding -> appearance sampling -> cutting -> size sampling;

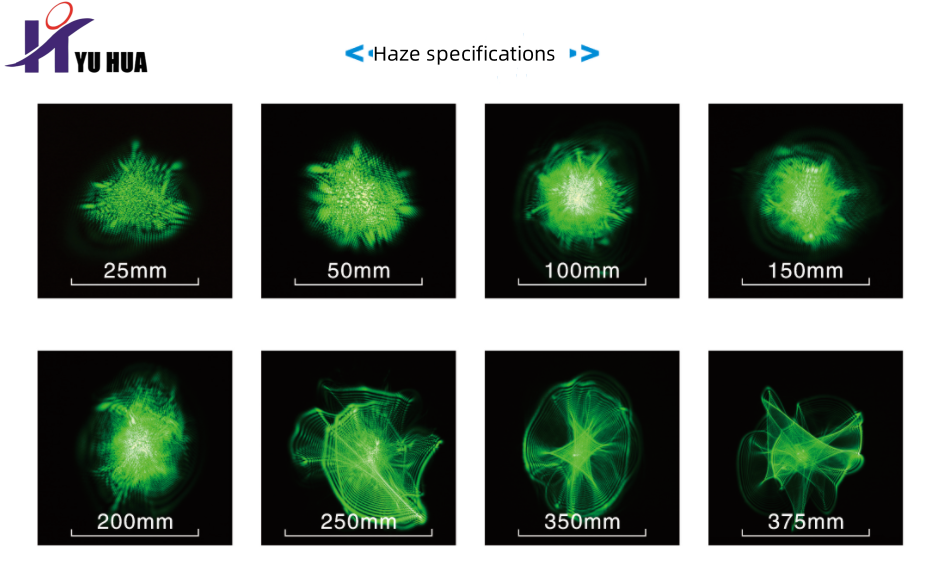

Focus on calendering printing, which is the step to form the scattering effect of greenhouse glass and different haze specifications. Different rollers can produce different haze specifications. According to different rollers, the haze specifications that can be produced are: 5, 10, 20, 30, 40, 50, 70, 75.

Note: Haze does not affect the price of glass, nor does it affect the transmittance of glass. The effect of haze is the hemispherical transmittance of glass (hemispherical transmittance is the average value of the light received by the greenhouse all day long).

Hemispherical transmittance is inversely proportional to haze. The higher the haze, the lower the hemispherical transmittance, and vice versa.

The glass specifications produced here are ultra-white diffused glass, which is non-tempered and has a transmittance of 91.5%.

Next is the tempering process (still taking Yuhua glass as an example)

Yuhua's tempering process is: edge grinding -> cleaning and drying -> hardness sampling -> tempering

The glass here can be used. It is ultra-white scattering tempered glass, and has eight different haze specifications. The patterns are divided into three types: pear, double velvet, and cloth. The light transmittance is 91.5%, and the self-explosion rate after tempering is 0.2%, and the self-explosion particle size is kept within 5x5cm2. ≥60 particles.

The tempered greenhouse glass can be installed and used. For other types of glass, not only the tempering standards are improved, the haze selection is more, and the light transmittance is 1% higher.

The final coating process (still taking Yuhua as an example)

Yuhua's coating process is: cleaning -> etching -> cleaning -> drying -> optical sampling -> packaging and warehousing;

After coating, it is Yuhua's highest transmittance anti-reflection glass, 97.5% transmittance, and has the characteristics of multi-fog, high safety, high scattering, and long life.

This is already the best glass specification currently used in greenhouses. The transmittance of 97.5% is already the ceiling of greenhouse glass.

Those who know about glass may notice that the etching process is used here, not the sol-gel process. The artistic component of Yuhua greenhouse anti-reflection glass lies in the etching process.

The etching coating process is a double-sided coating process. Through the proportioned chemical solution, a 120nm coating layer structure is etched on the surface of the glass. This film layer is etched on the surface of the glass, so the film layer and the glass are integrated, and the hardness of the film layer is the same as that of the glass body.

As the name suggests, the sol-gel process is an additional structure of the glass. Film is applied to glass, so there is an essential difference between the material and glass. Since it is a film, there is a risk of falling off, aging, and wear.

Compared with the sol-gel process, the etching process has inherent advantages, which is more durable, wear-resistant, and has a long life.

The above is the entire production process of Yuhua greenhouse glass, so when we choose greenhouse glass, we already have a goal.

For small-area display greenhouses and experimental greenhouses, anti-reflective glass is recommended.

For large-area planting greenhouses, anti-reflective glass is recommended.

For seedling greenhouses, scattering glass is recommended.

For restaurant greenhouses, scattering glass is recommended.

Next is how we distinguish greenhouses on the market, because scattering glass is just a name, you can call it, I can call it, and the distinction must mention two standards, [light transmittance] [haze];

[haze] is the scale of scattering glass; 50 haze and 70 haze correspond to different scattering sizes and hemispherical light transmittance. Haze is proportional to the scattering size and inversely proportional to the hemispherical light transmittance. When purchasing glass, the first test data you ask for from the merchant is haze.

[Light transmittance] is the hard-core data of greenhouse glass. Currently, it is divided into two types: 91.5% (this is the basis) and 97.5%+ (this is the ceiling). If it is lower than 91.5%, the greenhouse capacity is considered, and if it is higher than 97.5%, the greenhouse investment is considered.

For the price of greenhouse glass, you can consult Yuhua Factory. The light transmittance of Yuhua greenhouse glass can be as high as 99%, and there are 8 haze options including 5/10/20/30/40/50/70/75. Yuhua® also supplies glass to greenhouse project companies such as Havecon, Kubo and Van Der Hoeven. For more information, please contact us at overseas@hnyxlc.com.

Tags:anti-reflective glass diffuse glass agricultural greenhouses glass greenhouse venlo greenhouse AR glass greenhouses glass agricultural glass horticultural glass #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #GlassManufacturer #invernadero #ArchitecturalGlass #ClearFloatGlass #FloatGlass

Previous:About the bursting of tempered glass