How To Tell The Quality Of A Tempered Glass Panel Is Good Or Bad

Tempered glass (toughened glass) is produced by heating glass to just below the melting point (around 650℃) and then rapidly cooling it. In this way, the compressive stress on glass surface is generated and the strength of the glass is 4 to 5 times stronger than ordinary annealed glass.

For finished tempered glass panels, how to tell its quality is good or not?

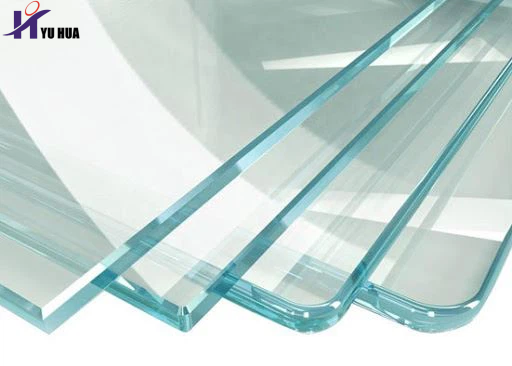

a. Materials: The good quality float glass materials have a clearer color and there will be no visible bubbles, solid impurities, less nickel sulphide inclusion. Nickel sulphide is the key factor that leads to the onsite spontaneous breakage of toughened glass.

b. After glass is tempered, the polished edges look shinier, smoother, and more good-looking. As we all know, all tempered shower doors at customized sizes requires shiny polished edges.

c. Also, the flatness of a well-tempered panel is much better and optical deformation is much less.

d. The pits caused by tempering also rarely occur.

e. Center punch fragmentation test could also be performed to tell the tempering quality. But after punching, the glass panel will break into blunt particles and can't be used any longer.

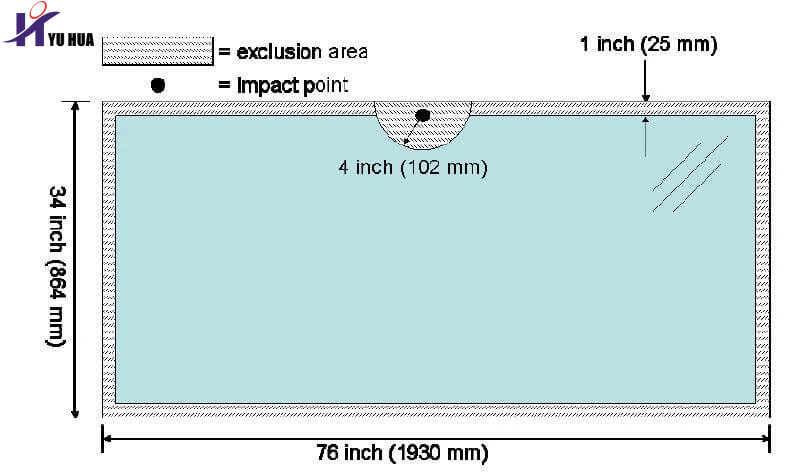

Below is how to perform the test according to ANSI Z97.1 2015.

(1) The total weight of the ten (10) largest crack-free pieces shall weigh no more than the equivalent weight of 10 square inches (6452 mm2) of the original test sample. (The weight in ounces of 10 square inches of glass is equal to 14.5 times the glass thickness in inches. The weight in grams of 10 square inches of glass is equal to 412 times the glass thickness in inches (16.18 grams/mm)).

(2) No one particle shall be longer than 4 inches (102 mm) excluding an area of radius 4 inch (102 mm) centered on the impact point, and a border of 1 inch (25 mm) around the entire perimeter/edge of the test specimen.

The diffuse glass and AR-coated diffuse glass produced by Yuhua have cooperated with many large commercial greenhouses in agriculture, horticulture, nurseries and experiments. We have cooperated with large greenhouse project companies such as Havecon, Van Der Hoeven, Kubo, etc. for many years. Yuhua greenhouse glass has a light transmittance of up to 99%, and haze 5/10/20/30/50/70/75 greenhouse diffuse glass is available!

Need more detailed information or a solution of greenhouse glass? Need guidance on how to choose the right glass for your greenhouse?

Consult online customer service, leave us a message or send us an email!

Tags:anti-reflective glass diffuse glass agricultural greenhouses glass greenhouse venlo greenhouse AR glass greenhouses glass agricultural glass horticultural glass #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #GlassManufacturer #invernadero #ArchitecturalGlass #ClearFloatGlass #FloatGlass

Previous:Introduction to Common Glass in Glass Greenhouses

Next:Poly Tunnel vs Greenhouse: Which is Better for Your Crops?