Problems and solutions caused by improper glass storage

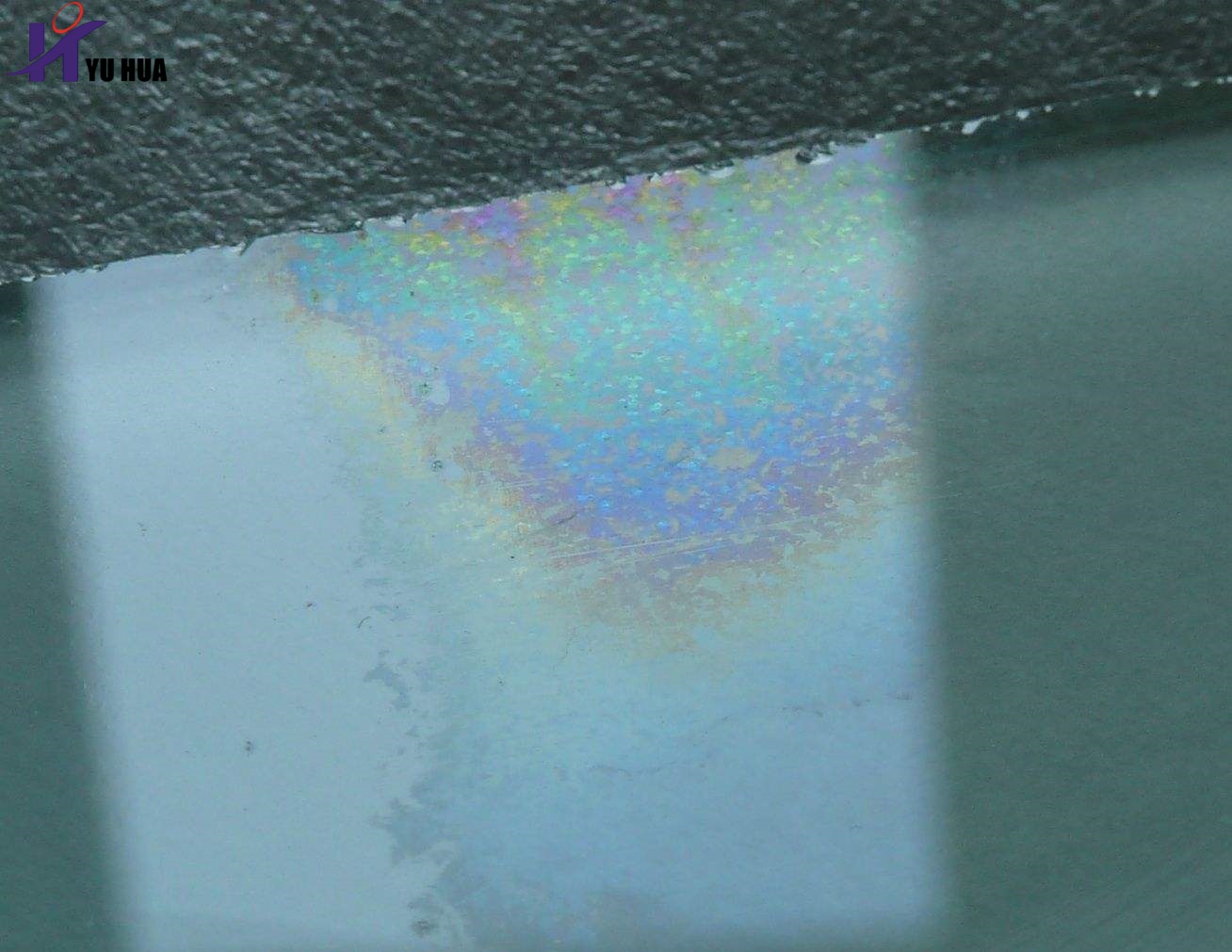

Normal glass does not have the problem of "aging" in the natural environment. The chemical composition of glass is very stable. In the natural state, the performance of glass will not be weakened by sunlight, rain, and fog. It can also resist common acid and alkali erosion. Generally, there are two conditions that affect the life of glass, humid air and high temperature. Chemical reactions caused by long-term storage of glass or humid weather. Under sunlight, rainbows, mildew spots/spots, watermarks, oil prints, paper grains and other phenomena will appear on the surface of the glass, commonly known as glass mildew spots, also known as anti-alkali.

When the glass interlayer is stored in a warehouse or exposed to rain, it is more likely to mold. Generally speaking, untreated glass is more likely to mold than untreated glass. We can use white vinegar to deal with the anti-alkali phenomenon. The combination of incandescent lamps and alkaline lamps will produce a chemical reaction, which can effectively prevent gas mold. Gas mold will affect the performance of glass, for example: the transparency of the glass is reduced, affecting the optical performance; white spots and mildew spots appear on the surface of the glass, affecting the deep processing of glass coating, mirror making, etc.; the mechanical strength of the glass is reduced; stains will be produced when the degree of mold is serious, and the incandescent lamp box of the gas will be scratched. At present, the main methods to prevent the cold end of glass from getting moldy are paper clip method, anti-mold powder method, anti-mold liquid method, etc.

1. Paper clip method

Paper can absorb moisture and prevent large areas of scale from forming on the surface of the glass, thereby effectively preventing the glass from getting moldy. The better the quality of the paper, the better the anti-mold effect. The paper clip method has a certain anti-mold effect, but the anti-mold time is short. Once the glass exceeds the validity period, the paper clip method will produce paper scraps on the glass, which is not easy to clean and is also a kind of damage to the glass.

2. Anti-mold powder method

The anti-mold powder method is to sprinkle anti-mold isolation powder on the glass. It is an economical, safe and effective method, and it is also the most widely used method in the industry. Before spraying, apply static electricity to the powder so that the powder is evenly distributed and firmly adsorbed on the surface of the glass plate.

3. Anti-mold liquid method

This method takes advantage of the volatility of the anti-mold liquid. It is not suitable to condense water vapor on the glass plate. Instead, a layer of anti-mold liquid should be applied on the glass plate and wait for it to dry naturally.

High temperature shock can cause thermal cracking of glass, which often occurs on sunny days in winter. This is because the heat generated by low temperature sunlight in winter causes a temperature difference in the plane direction of the glass sheet, forming thermal shock and thermal cracking. The key to preventing this phenomenon is not to store the glass in the open air, or to cover the glass with a layer of shielding cloth.

Glass storage should comply with the following precautions:

1. The storage location of the glass should be away from the construction site and places with frequent traffic, and should not be stored in places with strong winds.

2. The glass should be stored in a dark, dry and ventilated place or indoors with a roof to avoid direct sunlight. Untempered glass is more susceptible to heat than tempered glass.

3. The glass should be stored vertically, with an angle of about 70°-80°between the glass and the ground. The top should be against a solid object. There should be soft pads between the glass and the glass. The bottom can be raised with wooden boards or other soft materials, more than 100mm from the ground.

Tags:anti-reflective glass diffuse glass agricultural greenhouses glass greenhouse venlo greenhouse AR glass greenhouses glass agricultural glass horticultural glass #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #greenhouseglass #Antireflectiveglass #Diffusetemperedglass #Ultrawhitefloatglass #agriculturalgreenhouseglass #diffuseglass #horticulturalglass #Tomatogreenhouse #Coloredpeppergreenhouse #Lettucegreenhouse #Agriculturalgreenhouse #ARglass #venlogreenhouse #GlassManufacturer #invernadero #ArchitecturalGlass #ClearFloatGlass #FloatGlass

Previous:We sincerely invite you to visit Yuhua Glass booth for communication!